- Facilities at a Glance

- All Facilities

- Material

- Earth System and Environment

- Engineering Technology

- Space and Astronomy

- Particle and Nuclear Physics

- Energy

- Biology

- 1

- 2

- 3

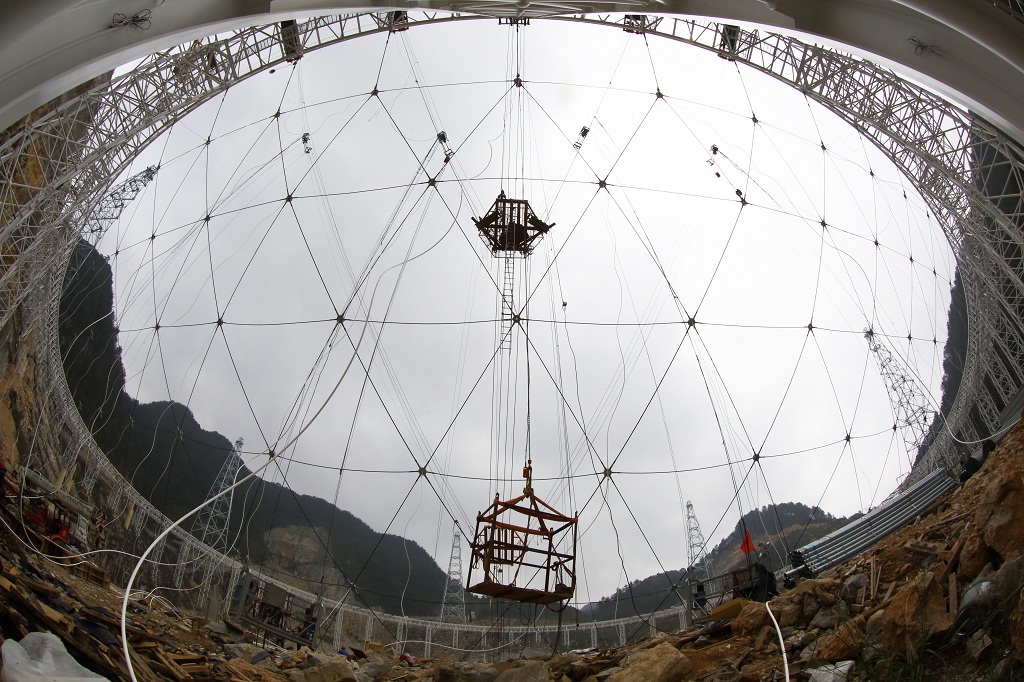

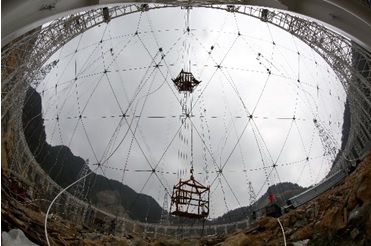

Five-hundred-meter Aperture Spherical radio Telescope (FAST)

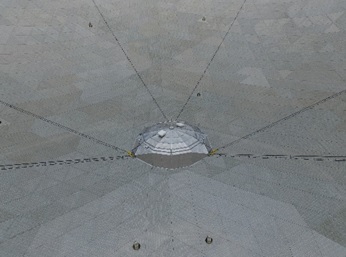

Five-hundred-meter Aperture Spherical radio Telescope (FAST) is a Chinese mega-science project to build the largest single dish radio telescope in the world, which aims to build a 500 diameter active reflector radio telescope on a karst depression in Guizhou province, in order to provide large sky-coverage and achieve high sensitivity for astronomical observations. On March 25, 2011, the construction of FAST was commenced. On September 25, 2016, the main structure of FAST was completed as scheduled. Acclaimed as the China Sky Eye, FAST is the world’s largest single-dish and the most sensitive radio telescope with China's own intellectual property rights.

The construction of FAST composes of five systems, including site and earthwork, active reflector, cabin suspension, measurement and control, receiver and observatory.

Compared with the Arecibo 305-m radio telescope, FAST has three outstanding aspects: its site is a deep and round karst depression named Dawodang in Guizhou province, it uses an active reflector to correct spherical aberration, and it has a lightweight feed cabin driven by six cables and a servomechanism plus a parallel robot for closed-loop precision control.

The exquisite sensitivity due to its size is ideal for large-scale surveys. FAST will enable astronomers to get a jumpstart on many science goals — for example, surveying the neutral hydrogen line emission from the distant galaxies out to very large redshifts that would provide significant information on the origin and evolution of the Universe, detecting thousands of new pulsars, that may uncover the law of extreme objects, etc.. Even higher sensitivity can be achieved by joining FAST with the international Very Long Baseline Interferometry network. This system may be able to resolve the fine structures of weak thermal sources, to get a close-up on the origin and evolution of stellar sources, and even to directly image the radio-loud extrasolar systems.

The story of FAST dates back to 1994, with the submission of the initial proposal. It was 2007 before the funding proposal gained approval. In 2011, the building phase of the project commenced. The girder ring of FAST to support the cable-net of reflectors was fully formed in December 2013, and on July 17, 2014, the installation of the cable-net itself followed suit. On 3 July 2016, the last of the 4,600 reflector elements was successfully placed. Meanwhile, the feed support system including six support towers and feed cabin housing the secondary adjustment system were constructed. The hardware and software for the measurement and control systems has been developed to ensure the high precision of astronomical observations. In addition, seven sets of receivers were designed and constructed based on international cooperation, such as the construction of the 19-beam receiver for FAST by the Commonwealth Scientific and Industrial Research Organisation in Australia. In order to protect the radio environment of the FAST site, the local government established a radio quiet zone with a radius of 30 km in 2013. On September 25, 2016, the main structure of FAST was completed after five and a half years of construction. Since then, the telescope has moved into the commissioning and test observation phase.

A single-pixel receiver covering the 270–1,620 MHz band has been designed and mounted at the feed cabin, providing a platform for observations during the early stages of operation. In May, 2018, the 19 beam receiver was installed, and the efficiency of telescope's survey will be greatly improved.

In 2017, FAST functional commissioning was basically completed. FAST has achieved several of observation modes such as pointing, tracking, drift scanning, etc. Reflector surface accuracy and feed pointing accuracy, telescope efficiency have satisfied the needs of scientific observation requirements basically. On October 10, the first discoveries of six pulsars observed by FAST were announced. The first one is numbered as J1859-01(FP1-FAST pulsar #1), with the rotation period of 1.83 seconds, which is estimated to be 16,000 light-years away from the earth. And it was found by drift scanning on the southern sky of galactic plane on August 22 and was confirmed by Parkes telescope on September 12. This is the first time that new pulsars were discovered by China's radio telescope.

On February 27, 2018, FAST first discovered a radio millisecond pulsar (MSP) coincident with the unassociated gamma-ray source 3FGL J0318.1+0252 in the Fermi Large Area Telescope (LAT) point-source list, which was confirmed by the Fermi-LAT team in reprocessing of Fermi data on April 18. The newly discovered pulsar, now named PSR J0318+0253, with a spin period of 5.19 milliseconds, an estimated distance of about 4 thousand light-years, and as potentially one of the faintest radio MSPs. This is another milestone of FAST.

FAST has discovered 59 pulsar candidates in high quality, and 44 pulsars have been confirmed so far (July 16, 2018).

FAST is a large scientific device of which China owns the intellectual property rights independently. It was designed, developed, manufactured and managed by Chinese scientists. A series of key technologies have been developed and a number of technological breakthroughs have been achieved: high strength and high precision large span cable net structure, high performance moving fiber optic cable, and large scale and high precision real-time measurement system, etc., which have promoted scientific and technological progress and industrial upgrades in many high-tech fields in China. FAST’s exclusive innovations hold the important practical values that meet the major demands of our country. It will greatly promote the economic prosperity and social progress in the western region of China.

The receiving area of FAST is equivalent to about 30 football fields. Its overall performance and sensitivity are several times higher than the existing telescopes and it is expected to maintain a leading position in the next 20 years. The innovative engineering concept and design of FAST paves a new road to realize a huge single dish in the most effective way.

FAST will be under commissioning until it reaches the designed specifications and becomes a Chinese national facility.

Equipment

-

Cable-net

The cable-net of FAST is a flexible cable structure with the largest span and highest accuracy in the world, also the first cable structure working in the way of active deformation as well. The cable-net comprises of 6670 main cables, 2225 node disks and 2225 down-tied cables. Imposed by 2 million load cycles, its main cable can bear a fatigue stress up to 500MPa. The manufacture error of main cable in length is controlled within 1mm at ordinary temperature(20℃). Both are far exceeding relevant industry standards. Each node disk is connected with a hydraulic actuator via a down-tied cable and anchored to the ground. The active deformation of the cable-net is realized by a coordinated stroke control of a group of actuators. -

Supporting towers

Supporting towers are the main load-bearing structures of the feed support system of FAST. They comprise of 6 steel pipe towers, each of which is more than 100m hight and the highest is 170m. The 6 towers stand around the depression in a 600m-in-diameter cycle with a uniformly-spaced and axisymmetric arrangement. They can bear cyclic cable tension imposed by the cable robot with the maximum up to 400KN. The 6 towers are named after clock according to their positions, namely 1H, 3H, 5H, 7H, 9H and 11H respectively. -

Cable Robot

The cable robot of FAST is the largest flexible-cable-driven parallel robot in the world that spans up to 600m. It is made of 6 sets of driving mechanisms, machine rooms(including eletrical rooms), pulleys, steel cables, cable suspensions for power supply and signal transmission, electrical devices and control units.

The cable robot lifts the feed cabin airborne and drives it to move in the so-called focal surface, which is 140~180m high above the ground, about 206m in aperture and 160m in curvature radius, and where the cabin is driven to roughly track and locate astronomical trajectory. It is an innovative breakthrough in building giant single-dish radio telescope in that rigid-structure design of feed support like Arecibo is given up. The weight of feed platform might be nearly 10000 tons supposing that Arecibo mode was simply copied, but it is now reduced to only 30 tons according to the cable-robot design. Moreover the weakness of wave-shielding almost diminishes. -

The feed cabin

The feed cabin is a complicate unit integrated together with all kinds of devices, such as optics, mechanism/mechatronics, electrics & electronics, measurement and control. It devotes to real-time pose adjustment and compensation of the mounted receiver platform, achieving high accuracy of tracking and positioning for the feed support system as required by FAST observation. The cabin is 13 meters long in diameter and 6.5 meters high, and weighs 30 tons. Its main compensators include an AB-axis rotator (orthogonal-two-axis rotator) and a Stewart platform (hexapod). The rotator can compensate pointing angle of the receiver up to ±18° around each of the two orthogonal axes. The Stewart platform plays as role of the secondary fine-tuning because it further compensates the residual pose errors of the receiver so that spatial positioning error is less than 10 mm in root mean square (rms) and orientation error less than 0.5°. -

Actuator

The actuator is driving unit used for active deformation of the main reflector system of FAST. It is a hydraulic cylinder integrated with low pressure, small pump displacement and gear pump control, which is innovatively developed for the special demand of active deformation of FAST and resist of rough outdoor environment. Its piston moves at low speed (<2mm/s), but with high positioning accuracy (error less than 0.02mm) and high position-holding accuracy under static full load (error less than 0.1mm/h). -

Reflector elements

There are 4450 reflector elements in total, each of which is aluminum structure. Each triangular element is ~11 meters long and holds an area of ~50 square meters. The total structure is made of back structure (spatial truss) and slightly concaved plane panel, with its 3 vertices connected with and constrained to the respective node disks of the cable-net. All panels are perforated up to 50% and the surface accuracy is better than 2mm. When the cable-net deforms actively to change its shape, it also pushes forward the mounted 600~700 elements to form paraboloid as demanded by FAST observation. -

The 19-beam receiver

The 19-beam receiver is a dedicated multi-beam receiver developed for FAST telescope. It is based on multi-horn array technology. The frontend consists of 19 identical horn and receiver, and it covers a frequency range of 1.05~1.45GHz. The 19 horns are arranged in a hexagonal pattern, with the central horn put at the focus, and the other horns on the focal plan of the FAST telescope. The corresponding far-field patterns of the 19 horns point to different regions on the sky, allowing a simultaneous observations of 19 regions on the sky. Compared with a single beam receiver, the 19-beam receiver will increase the speed of survey observations by a factor of 19.

The research and development of the 19-beam receiver was started after the international evaluation meeting of FAST in 2006. After an extensive discussion on science motives and engineering possibilities, and a feasibility study of the frontend through a trilateral collaboration among China, the UK and Australia, the 19-beam receiver was developed and built by the CSIRO in Australia. The receiver passed the review in 2017, and was installed and tested on the FAST telescope successfully by Chinese and Australian engieers in 2018.

The 19-beam receiver of FAST is the largest multi-beam receiver at L-band in the world. It plays an important role in the pulsar survey, FRB and neutral Hydrogen survey observations for the FAST telescope.

NOTICE

-

Call for Proposals for HEPS Phase II Beamlines May 23,2022